Ioniqa, one of our National Icons, is developing a new chemical upcycling method. The end product is a high-quality raw material equivalent to new plastic from oil. With this, 25 percent of global plastic production can be infinitely recycled, with 75 percent less CO2 emissions. Thanks to the Corona Bridging Loan (COL), the startup is off to a fast start after the corona crisis to clean up the growing plastic mountain.

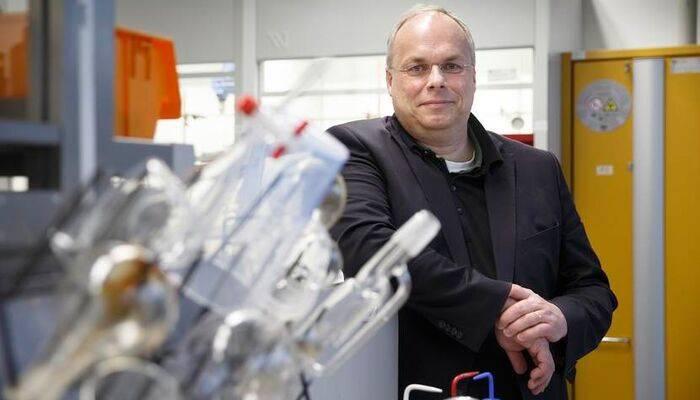

Ioniqa was founded in 2009 as a spin-off from Eindhoven University of Technology, where all R&D takes place. "We now also have two production facilities," says Tonnis Hooghoudt, one of the founders. "These are at Chemelot, the industrial complex for the chemical industry in Geleen, and in Rotterdam, where we collaborate with Unilever, among others, in a demonstration plant. The raw materials we make with our patented process meet the highest standards. They are suitable for food-safe packaging."

Ironically, the faltering economy has actually increased plastic waste. It is currently cheaper to produce new plastic from crude oil than to recycle it. But that's a temporary problem, Hooghoudt believes. "Under pressure from consumers, carbon taxes and increasingly strict legislation, all major manufacturers are working on plans to eventually become completely circular. Our technology closes the circle and is going to play an important role in the production of plastic."

"We have faced surprises before in the development of our business. Even this crisis did not turn out to be disastrous. But with the Corona Bridging Loan, we were able to avoid problems with our cash flow. The speed with which the scheme was announced and implemented gave us a lot of peace of mind and room to breathe. I am really impressed with the diligence and ease with which the regional development agencies have worked together. I had a very different picture of that."

Hooghoudt: "A crisis like this does make you think. Some changes will be permanent. But our plans remain unchanged. We are working on a process to upcycle polyester from textiles as well as PET from packaging materials. The plant in Geleen will also be up and running again. But that is only the beginning. Our goal is for manufacturers around the world to build similar plants under license. Making our technology available worldwide is what cleaning up the plastic mountain is all about. The technology works. We have already demonstrated that.

- Some 900 million small PET bottles pass over the counter each year in the Netherlands. An estimated 100 million of these end up in the environment.

- By introducing a deposit system for small bottles on July 1, 2021, State Secretary van Veldhoven wants to keep plastic bottles out of the environment.

- It is estimated that with this deposit system, 90% of plastic bottles can be recycled.