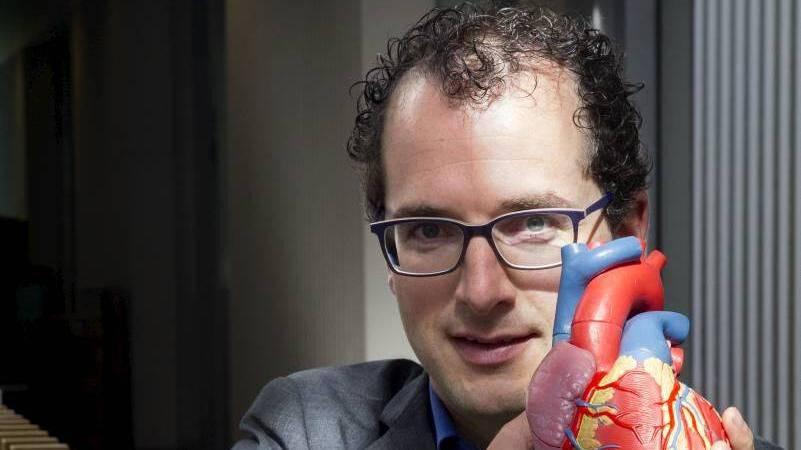

For several years, 18 children across Europe, Asia and the US have been living with an implanted, regenerative heart valve from the Eindhoven-based company Xeltis. Xeltis originated 13 years ago as a spin-off from Eindhoven University and is still based there, at Twice | hub Catalyst. In an interview with the trade magazine LABinsights, Martijn Cox, chief technology officer at Xeltis, talks about this strong example of supramolecular chemistry combined with regenerative medicine.

Library of materials

"Supramolecular chemistry allows us to develop a library of materials, ranging from very stiff to very stretchable materials, from very fast to very slow degradable substances. It's a much broader range of substances than you could achieve with ordinary chemistry," says Martijn Cox, chief technology officer and founder of the company in 2007. "The difference between supramolecular and ordinary polymers is that with supramolecular materials we use relatively short polymers that we can attach to each other like Lego blocks with hydrogen bonds. This is a principle that is also used in nature with DNA, for example. Hydrogen bonds by themselves are not very strong, but if you use a unit with several hydrogen bonds next to each other, it creates a strong and reversible bond. As a result, these materials are much stronger than you would expect based on their molecular weight," Cox explains.

Tissue repair

Xeltis uses these types of materials to make heart valves and pieces of blood vessels that can be implanted in people, Cox says. "We see that from day one our implants function like the body part they are replacing. But at the same time, they are also porous, although you can't see that with the naked eye. As a result, the implanted blood vessels leak for the first few minutes after implantation. But soon after, the blood coagulates in the material and cells settle there. These include cells from surrounding tissue and cells circulating in the blood such as macrophages and fibroblasts. Actually, the same thing happens that happens during tissue repair in a wound."

Over time, the plastic is completely filled and covered with the body's own tissue. "After about six months, the plastic loses strength due to oxidation of certain bonds, so it actually disintegrates into chunks. Because it is then completely encased in the new tissue, it can take years before it is completely gone."

Functional as a natural heart valve

What remains is then a new heart valve or blood vessel made of the body's own cells. "You will always be able to tell that it is not the same as a natural heart valve. For example, the implanted heart valve is slightly thicker and stiffer, but there are a lot of similarities and essentially there is no difference in function," Cox said. "Like a natural heart valve, for example, there is a layer of cells that keeps clots from forming, and there are capillaries through the material and networks of proteins such as collagen and elastin."

Success with children

Xeltis initially focused on developing heart valves for children. In an initial clinical trial, 12 children from Europe and Asia received such a heart valve from Xeltis. Initial results showed that there was still a slight complication, although the children noticed little. After the heart valves were adjusted slightly, a new trial was started last year in six children from the US. So far, no complications have occurred there, the researchers announced last February. "We hope that eventually the body's own tissue will also grow with the children, but there is no evidence of that at the moment. But even if it doesn't, our heart valve is already an improvement over current heart valves, which have to be replaced every few years because of wear and tear," Cox said.

High and low pressure

Meanwhile, Xeltis employees are busy developing other variants. While the first trial involved a heart valve on the low-pressure side of the heart, the company is now also working on a heart valve for the high-pressure side. For this, more requirements are being placed on the material. In addition, work is underway on the development of a blood vessel for bypass surgery, eliminating the need to use a blood vessel from the patient's leg. The first clinical trials with this are expected to start at the end of 2020.

This article appeared in LABinsights on June 26, 2020 .